| Product Name | SPK Steam Heat Shrink Furnace Label PACKING MACHINE |

| Specification | W200*H200MM |

| Furnace Size Furnace Cavity | 1300mm(L) Furnace Mouth Entrance*200(W)*200(H) |

| Machine Size | 2135*706*1370MM (Length, Width and Height) |

| Suitable for Shrink Film | PVC |

| Temperature Control | ≦100 Degrees |

| Conveying Speed | Adjustable, 15m/min |

| Power | 380V 50-60HZ |

| Total Power | 18KW |

| Platform Height | 750MM |

| Conveyor Belt | 304 Stainless Steel Mesh Conveyor Belt |

| Conveying Load | 10KG |

| Machine Weight | 380KG |

| Main Material | 304 Stainless Steel |

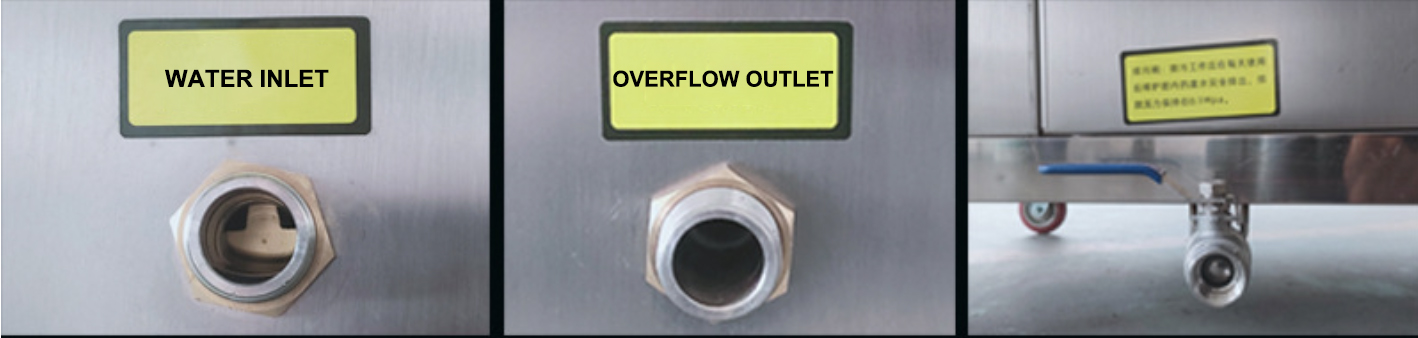

| Water Inlet Method | Directly Connected to a Clean Water Pipe With Pressure |

| Heating System | Built-in Steam Generator |

| steam Pressure | Atmospheric Pressure |

| Steam Saturation | 20-50KG/HR |

Product Advantage:

1. 10 years manufacture in packing machine 2. 100% QC inspection before shipment 3. 12 months warranty 4. Product Certificated by CE

5.Comes with a steam generator, no need to purchase a separate steam generator, saving space

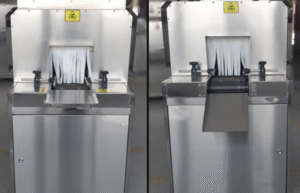

6.There are more types of products that can be packaged, including shaped bottles and various personalized design products Introduction: The steam shrinking machine adopts the latest steam shrinking technology with high heat shrinking efficiency, aiming at different and irregular round bottles, square bottles, oval bottles, etc;

Steam contraction adjustment: the whole machine is simple, with three layers of heat insulation to reduce heat loss, waterproof design, made of stainless steel 304, equipped with temperature and contraction at a glance, easy to start up and operate, each nozzle on both sides of the whole machine can adjust its up, down,left, right, inside position and jet direction, the front and rear end of the whole machine is equipped with outlet shield device to reduce steam leakage, heat preservation, and the whole machine body.

Steam contraction adjustment: the whole machine is simple, with three layers of heat insulation to reduce heat loss, waterproof design, made of stainless steel 304, equipped with temperature and contraction at a glance, easy to start up and operate, each nozzle on both sides of the whole machine can adjust its up, down,left, right, inside position and jet direction, the front and rear end of the whole machine is equipped with outlet shield device to reduce steam leakage, heat preservation, and the whole machine body.

1.Operation Panel

A concise and easy to understand control panel,Quick knob design function,Convenient to adjust the conveying speed at any time Fan speed and heating gear.

2.Exhaust Port

Steam discharge outlet, using Self suction exhaust fan is convenient for operation External connection of atomized steam moisture Let it be discharged outdoors.

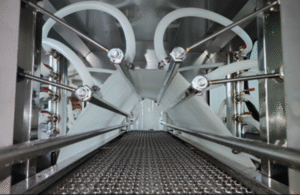

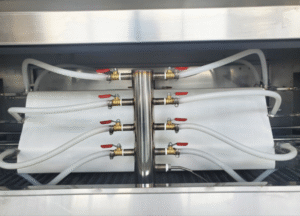

3. Steam Jet Pipe

Both sides are made of 304 stainless steel Spray nozzle, convenient and quick adjustment The upper and lower positions of the nozzle, as well as The direction of spraying.

4.Four Layer Jet Hole

Four layers on one side, eight rows in total, with jet hole design. The length, direction, and volume of the jet can be adjusted freely to achieve better contraction effect.

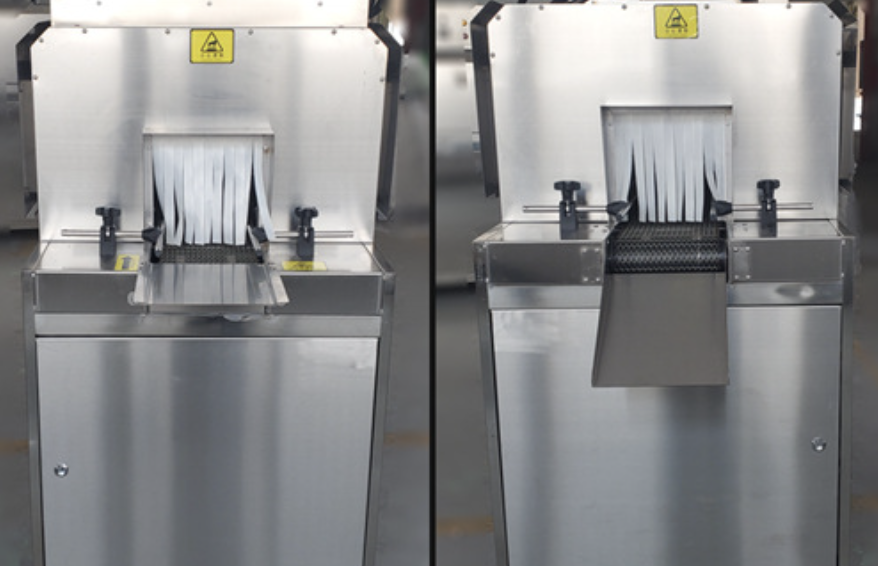

5.High Temperature Protective Curtain

Install furnace protection curtains at the front and rear entrances and exits respectively to reduce steam leakage.

6. Thermal insulation and Heat-Resistant Protective Plate

Both sides of the body are equipped with anti scalding devices partition board to prevent negligence be careful not to touch and

cause burns, it is safer to use.

cause burns, it is safer to use.

Application Products: