Technical Features:

Vacuum sealers can be used to vacuum package most kinds of foods as well as household items. However, there are certain guidelines

that should be followed to maximize the capabilities of your vacuum sealer:

Vegetables should not be vacuum sealed fresh. It is best to blanch them (place in boiling water until it is hot, yet still

crunchy), then submerge in ice water to stop the cooking process. This will allow the vegetables to retain their color and

firmness. You may then continue with the vacuum sealing. You can also freeze the fresh vegetables and then continue the vacuum

sealing process. If this is not followed, they will emit a gas after they have been vacuum sealed that will interfere with the

vacuum seal of the bag.

Any food, such as meat or fish, that is very moist, is the best vacuum sealed after it has been frozen. The excess moisture in the

food will interfere with the sealing phase. Likewise, more delicate foods, such as bread or fruit, which are likely to be

compressed under the pressure of vacuum sealing should also be frozen first to help the product hold its shape.

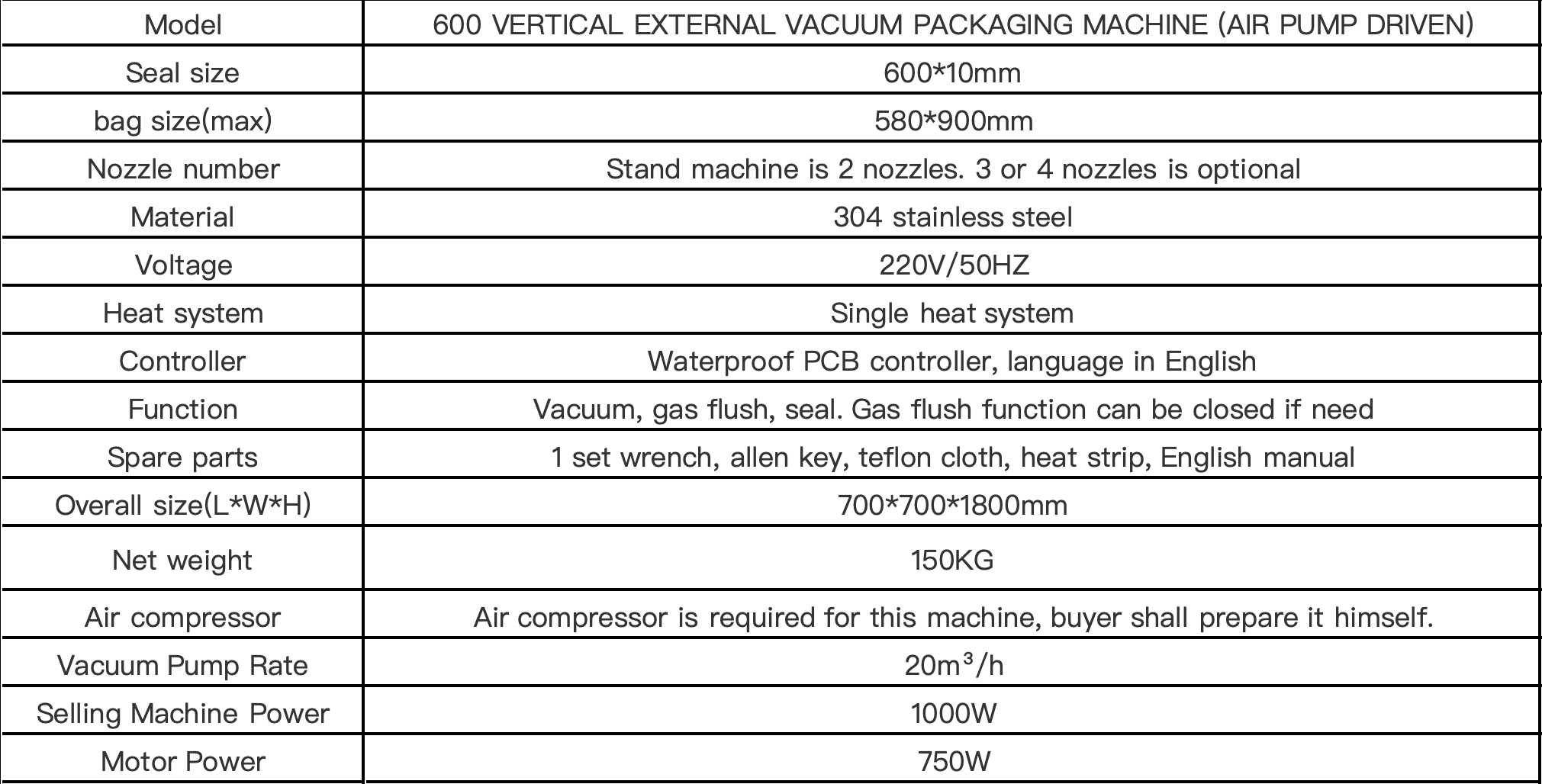

| Model | 600 VERTICAL EXTERNAL VACUUM PACKAGING MACHINE (AIR PUMP DRIVEN) |

| Seal size | 600*10mm |

| bag size(max) | 580*900mm |

| Nozzle number | Stand machine is 2 nozzles. 3 or 4 nozzles is optional |

| Material | 304 stainless steel |

| Voltage | 220V/50HZ |

| Heat system | Single heat system |

| Controller | Waterproof PCB controller, language in English |

| Function | Vacuum, gas flush, seal. Gas flush function can be closed if need |

| Spare parts | 1 set wrench, allen key, teflon cloth, heat strip, English manual |

| Overall size(L*W*H) | 700*700*1800mm |

| Net weight | 150KG |

| Air compressor | Air compressor is required for this machine, buyer shall prepare it himself. |

| Vacuum Pump Rate | 20m³/h |

| Selling Machine Power | 1000W |

| Motor Power | 750W |

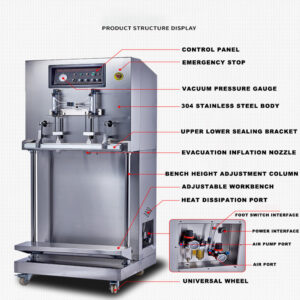

1.food grade 304 stainless steel

It has characteristics such as corrosion resistance, rust resistance, and durability. Ensure stable and long-lasting operation of the machine in various working environments.

2.Double nozzle design

Adopting stainless steel dual nozzles, efficient and durable, easily adaptable to various working environments

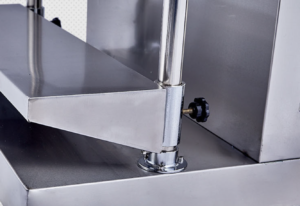

3.Workbench adjustment system

Black glue wood screws are used to adjust the height of the workbench, with an effective range of 30-900mm

4.The upper and lower sealing brackets are corrosion-resistant, sturdy, durable, and not deformed.

This machine is designed using large aluminum magnesium alloy molds and silicone materials, as well as internal and external double sealing strips. It has the characteristics of good sealing effect, corrosion resistance, durability, and no deformation

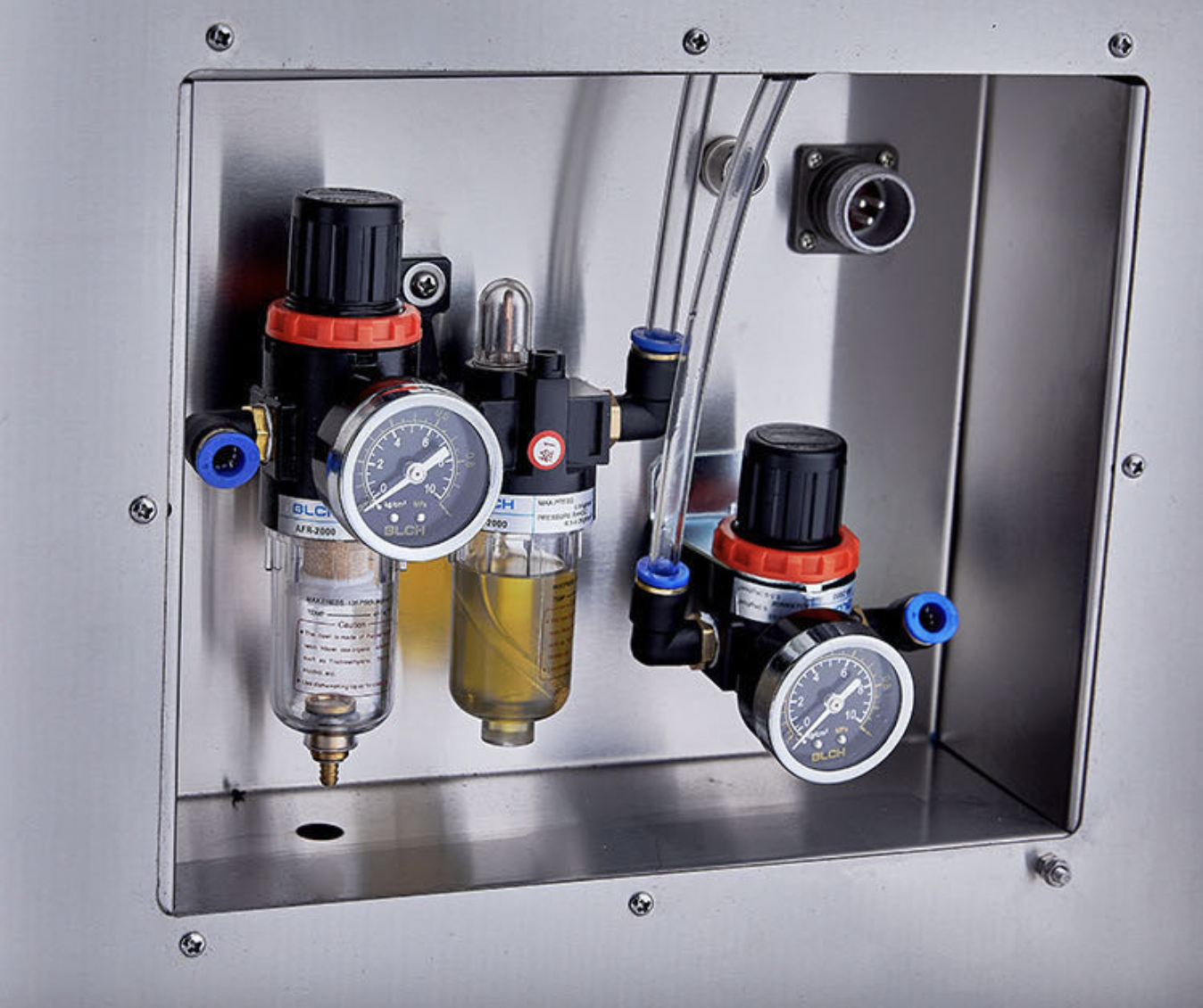

5.Oil water separation system

Effectively separate oil and water quickly, protecting the service life of pneumatic components.

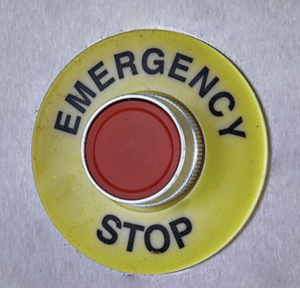

6.Emergency stop

The equipment is equipped with an emergency stop switch, which can be pressed to terminate all ongoing work in case of abnormal situations, ensuring personal safety

Advantage

— Support big bag and wide range of bags material also thickness.

— Only cost 15s-20s per cycle.

— Low gas consumption, and it can fill sufficient gas into bag.

— Easy to operate and maintain.

— Equipped with oil/water seperator and dust filter.

— Height of work table is adjustable.

— Flow of gas flush can be adjusted.

— Low noise.