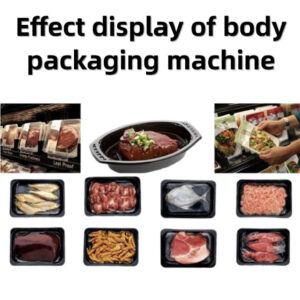

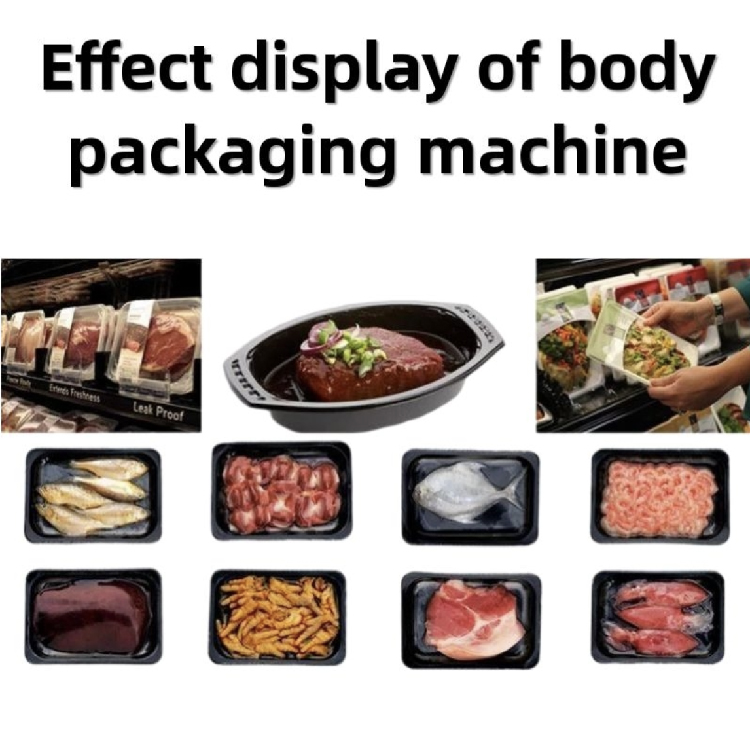

IY750 Commercial fresh food vacuum packaging machine meat skin film vacuum packing machine

Introduction of Vacuum Skin Tray Packing Machine

The skin vacuum packaging machine working principle: adopt the composite film with low viscosity, put the material on the tray or film of the lower template, in the vacuum state, send the heat generated by the heating plate to the vacuum room through the exhaust outlet, give the composite film with low viscosity instant whole body heating, compound together, to achieve the effect of vacuum packaging.It can keep the color, flavor and freshness of the product, and the packaging can improve the product grade in a three-dimensional way. Vacuum sealing, moisture-proof, anti-oxidation and dustproof can effectively protect the product and extend the product life.

Features of Vacuum Skin Tray Packing Machine

- The machine is made of food-grade 304 stainless steel body, which is firm, beautiful and corrosion-resistant, ensuring stable and lasting operation in any environment;

- The components used in the control panel are of good quality, the circuit layout is carefully designed, which is conducive to control and easy to operate;

- The quality of the interface is reliable, stable and fixed, which can effectively improve air pump inflation and work efficiency;

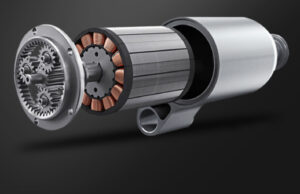

- Adopt high-quality vacuum pump to ensure production safety and product vacuum;

- It is not only applicable to products with hard or relatively stable materials, but also applicable to products with soft texture. After packaging, the product has a strong three-dimensional sense

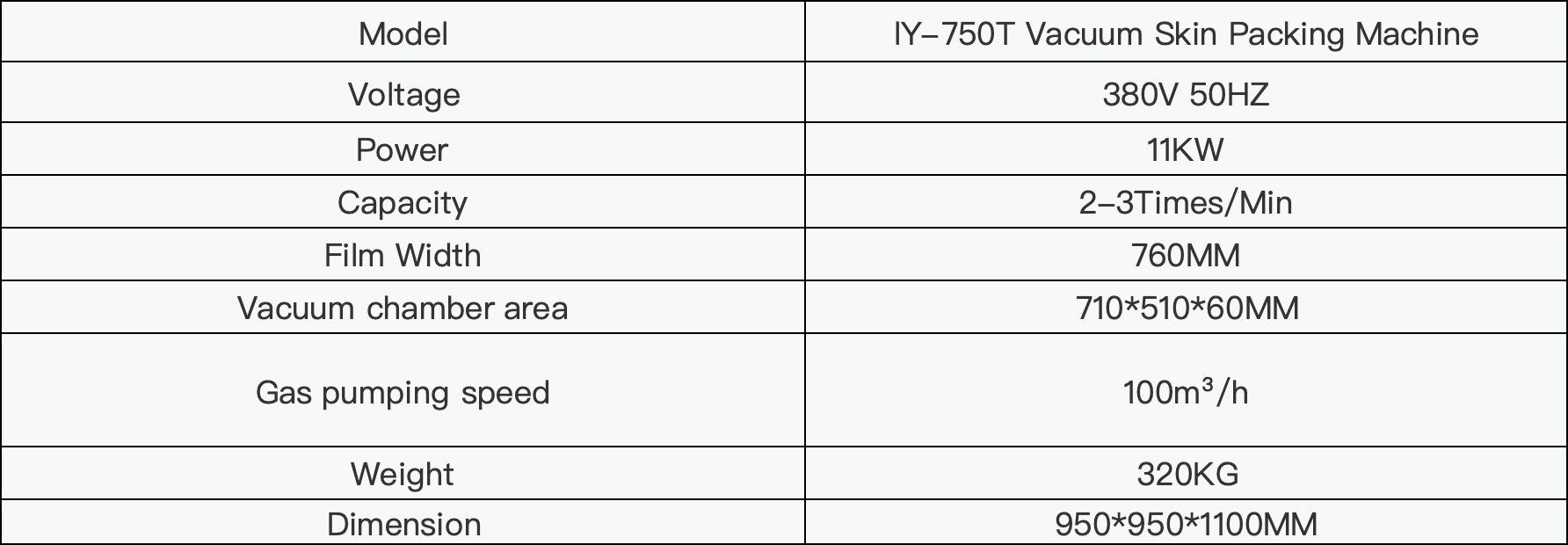

| Model | lY-750T Vacuum Skin Packing Machine |

| Voltage | 380V 50HZ |

| Power | 11KW |

| Capacity | 2-3Times/Min |

| Film Width | 760MM |

| Vacuum chamber area | 710*510*60MM |

| Gas pumping speed | 100m³/h |

| Weight | 320KG |

| Dimension | 950*950*1100MM |

Features

- vacuum skin packaging machine is made of food-grade SUS304 stainless steel and applies top quality BUSCH vacuum pump for best vacuum and skin pack quality

- Adjustable mold depth, pack skin pack trays with same length*width but different depth without changing mold

- Safety: Equipped with emergency stop; Alarm; Open-phase protector; anti-phase protector.

- Customize supply according to customer’s request

- Molds: Aluminum magnesium alloy molds, high strength, durable, corrosion-proof.

6.The shelf life is nearly double that of a traditional MAP package, and about four times longer than a stretch-wrapped product.

7.Food producers can include sauces and soups into packages without having them transfer between food components and purge .

8.Vacuum skin packaging is neat and compact, with the least printings, marks, and labels.

9.Bottle rigid trays can support and protect the food products during shipping, storage, and display.

- Panel with touch screen

This machine adopts electrical automation control, PLC programming combined with touch screen to achieve human-machine interface dialogue. The actions and control parameters of each part can be set and modified through PLC. Convenient and reliable operation control with low failure rate.

- Multiple mold packaging high efficiency

This machine is suitable for box type SMT vacuum packaging of various foods, automatically completing vacuuming, SMT, sealing and cutting, and discharging packaged products. (The box placement mold can be customized according to needs.)

- Heavy duty caster with brake

- High quality brand 100m3/h high-power vacuum pump