One-step shrink wrapper feature a seal and shrink process completed with the closing of a lid. Users place products into the shrink material, then slide the product into the chamber. With the close of the lid, the magnet holds down to make a seal, after the seal, heat shrinks the material to the product.

1.Economical, small footprint.

2.Suitable for low production packaging.

3.Low power consumption and small heat loss.

4.Not limited by the site, with wheels at the bottom, it is convenient to move.

|

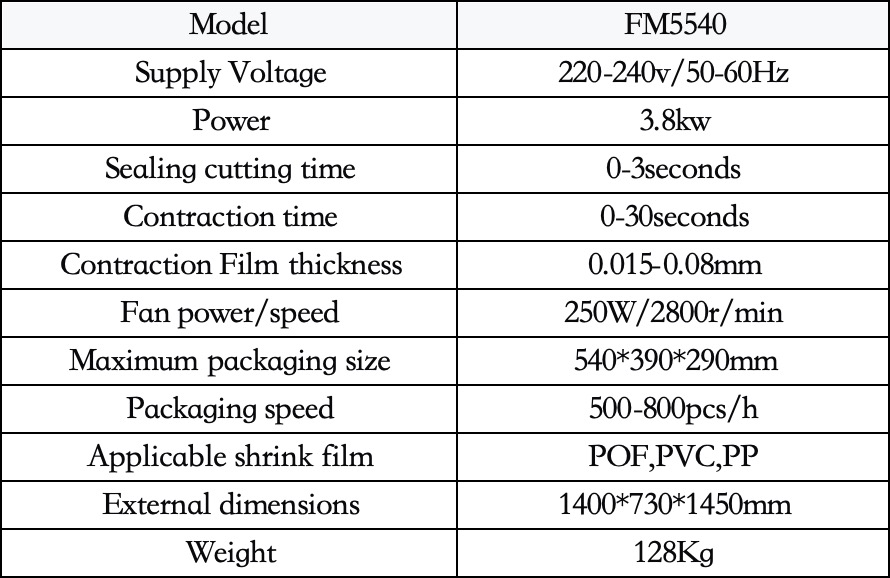

Model

|

FM5540

|

|

Supply Voltage

|

220-240v/50-60Hz

|

|

Power

|

3.8kw

|

|

Sealing cutting time

|

0-3seconds

|

|

Contraction time

|

0-30seconds

|

|

Contraction Film thickness

|

0.015-0.08mm

|

|

Fan power/speed

|

250W/2800r/min

|

|

Maximum packaging size

|

540*390*290mm

|

|

Packaging speed

|

500-800pcs/h

|

|

Applicable shrink film

|

POF,PVC,PP

|

|

External dimensions

|

1400*730*1450mm

|

|

Weight

|

128Kg

|

Advantages of two-in-one shrink packaging machine:

1.Large Fan

The large wind blade makes the shrinking furnace form a good wind circulation, and the uniform heating makes the film shrinking effect excellent.

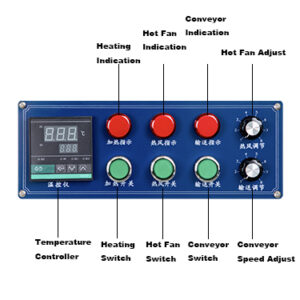

Independent control panel, easy to operate, quick and easy to set automatically.

3.High Quality Magnet

The plexiglass cover can be firmly sucked to prevent the temperature of the shrinking chamber from leaking, which effectively improves the working efficiency of the machine.

4.Stretchable Separation Membrane

The film separating plate can separate the two layers of the double-layer film by passing through the middle of the double-layer film to prevent the shrink film from sticking together.

5.Featured Pin Wheel Press Wheels

By evenly piercing the vent holes on the film, the shrink film can be prevented from breaking during the shrinking process and the shrinkage quality can be improved.

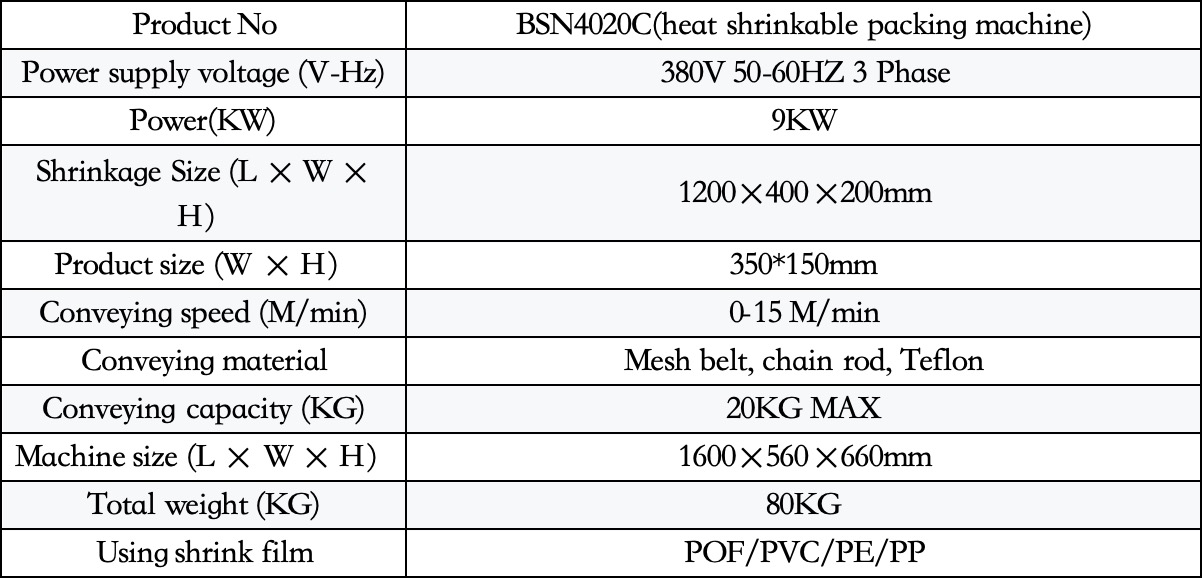

| Product No | BS4020(heat shrinkable packing machine) | |

| Power supply voltage (V-Hz) | 380V 50-60HZ 3 Phase | |

| Power(KW) | 9KW | |

| Shrinkage Size (L × W × H) | 1200×400×200mm | |

| Product size (W × H) | 350*150mm | |

| Conveying speed (M/min) | 0-15 M/min | |

| Conveying material | Mesh belt, chain rod, Teflon | |

| Conveying capacity (KG) | 20KG MAX | |

| Machine size (L × W × H) | 1600×560×660mm | |

| Total weight (KG) | 80KG | |

| Using shrink film | POF/PVC/PE/PP | |

Product Advantage:

1. 10 years manufacture in packing machine

2. 100% QC inspection before shipment

3. 12 months warranty

4. Product Certificated by CE

Introduction: BSN4020C far-infared shrink packing machine. It adopts shrink film to pack products,then heat to shrink package material,tighten products. Packed articles can be sealed,damproof,divtyproof and protect thenselves from outside shock&have buffer function.

Features: 1. Advan-ced design,stable performance,good shrink,easy to operate and maintain. 2. Creative automatic roll device can work continucusly. 3. Using quartz fat-infared capsule to heat ,saving more than 15%.

1.Shrink Tunnel Material

Standard configuration is net conveyor . Mesh conveyor and chain conveyor need to be customized.

2.Independent Control Panel

The temperature and the speed of conveyor is adjustable. Can adjust conveyor,heater and wind system individually.

3. Net Conveyor

Stainless Net Conveyor Is Suitable For Small Contact Area Products,More Stable And Safe.

4.Quartz Far Infrared Heating

Continous heating make the products be heated evenly.

5.Heat Block Cloth

Cloth protect from buring when working.

6. Power Cord Description

Due to the large power of the machine, the power cord of this machine does not have a plug, only the cable line, and the customer needs to connect it to the circuit breaker.