Desktop manual vacuum skin tray sealing packaging machine is suitable for vacuum skin fresh-keeping packaging of cooked food, cold fresh meat, seafood, fast food and so on. The equipment has compact design, reasonable structure and simple operation. It is equipped with a small vacuum pump and OMRON temperature control system. It could provide stores and small-scale food processing units with vacuum skin food packaging with Quality assurance, fresh preservation, Color preserving, shape maintenance and Flavor preservation.

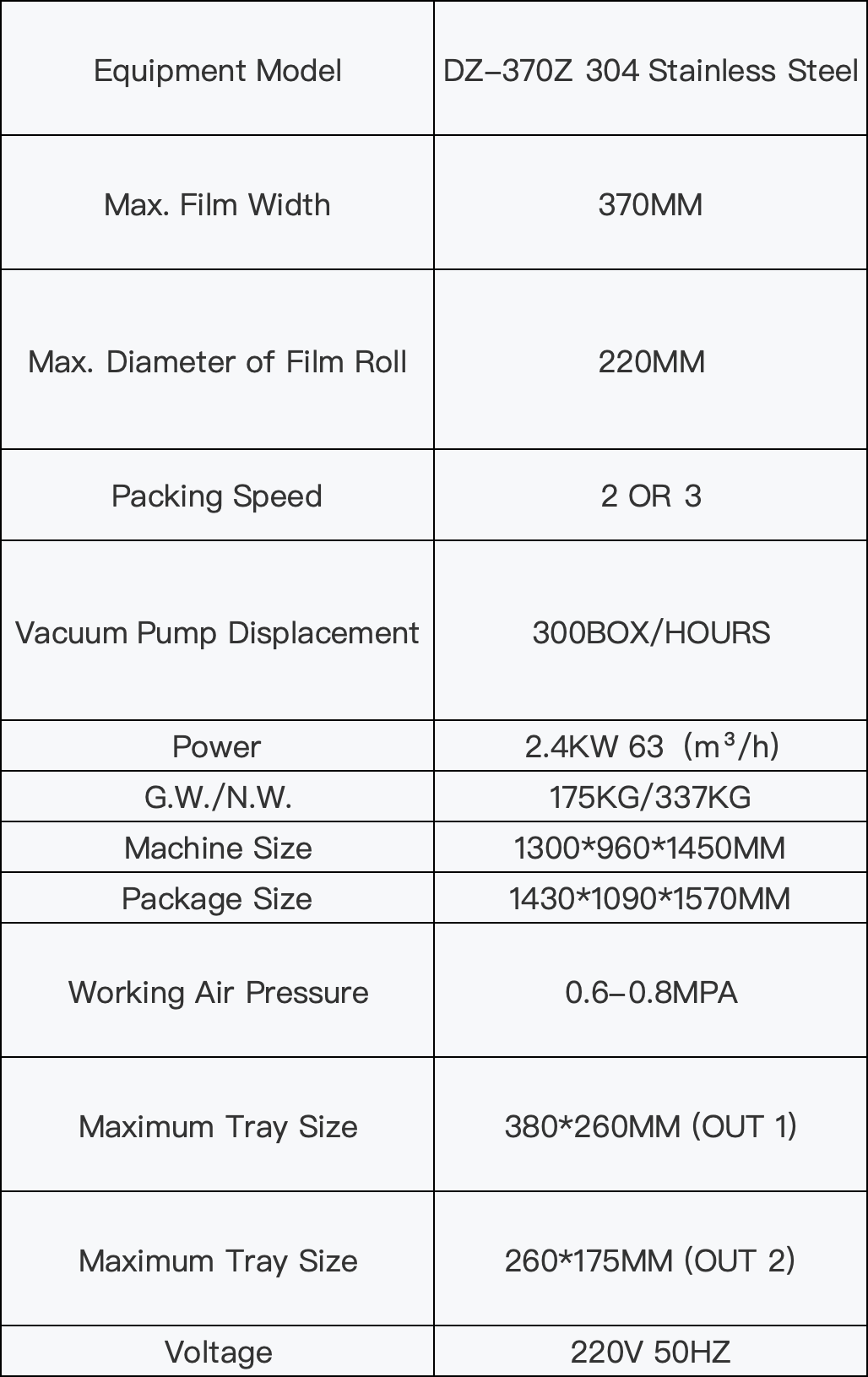

| Equipment Model | DZ-370Z 304 Stainless Steel |

| Max. Film Width | 370MM |

| Max. Diameter of Film Roll | 220MM |

| Packing Speed | 2 OR 3 |

| Vacuum Pump Displacement | 300BOX/HOURS |

| Power | 2.4KW 63(m³/h) |

| G.W./N.W. | 175KG/337KG |

| Machine Size | 1300*960*1450MM |

| Package Size | 1430*1090*1570MM |

| Working Air Pressure | 0.6-0.8MPA |

| Maximum Tray Size | 380*260MM (OUT 1) |

| Maximum Tray Size | 260*175MM (OUT 2) |

| Voltage | 220V 50HZ |

1.Food grade 201 OR 304 stainless steel body

Corrosion-resistant, rust-resistant and durable, it ensures the stable operation of the machine in various environments and prolongs the service life of the machine.

2.Food grade mold6061 anodized aluminum

Corrosion resistance,impact resistance, no deformation, no rust, ensure food safety and prolong the service life of the mold

3.Highly integrated control system easy to operate

4.Dual safety start buttonDouble preservation

The machine can be started only when the two buttons are operated at the same time, which can prevent safety accidents caused by improper operation or naughty children in the production process.

5.high quality vacuum pump

High quality and high-power brand vacuum pump, pure copper coil, strong power, better vacuum effect, and longer service life

6.Double hand swelling axis film collection and precise film moving system

The brand new dual hand expansion axis film collection system maintains the horizontal stability of the film, and the film replacement is simple, convenient, and precise