DZ 600 2QX Gradient Double chambers vacuum packaging machine

1, very simple and convenient to use

2, fits for stores, supermarkets and family

3, it is easier and quicker to change the sealing heating wire

4, sealing temperature range is extensive so that this machine can fit for different materials of packaging bags

5, food grade stainless constructions

6, on Control panel there is a emergency “stop” button, if the packing turn to be abnormal in the process of air extraction, push down the emergency “stop” button, that is stop the packing procedure immediately

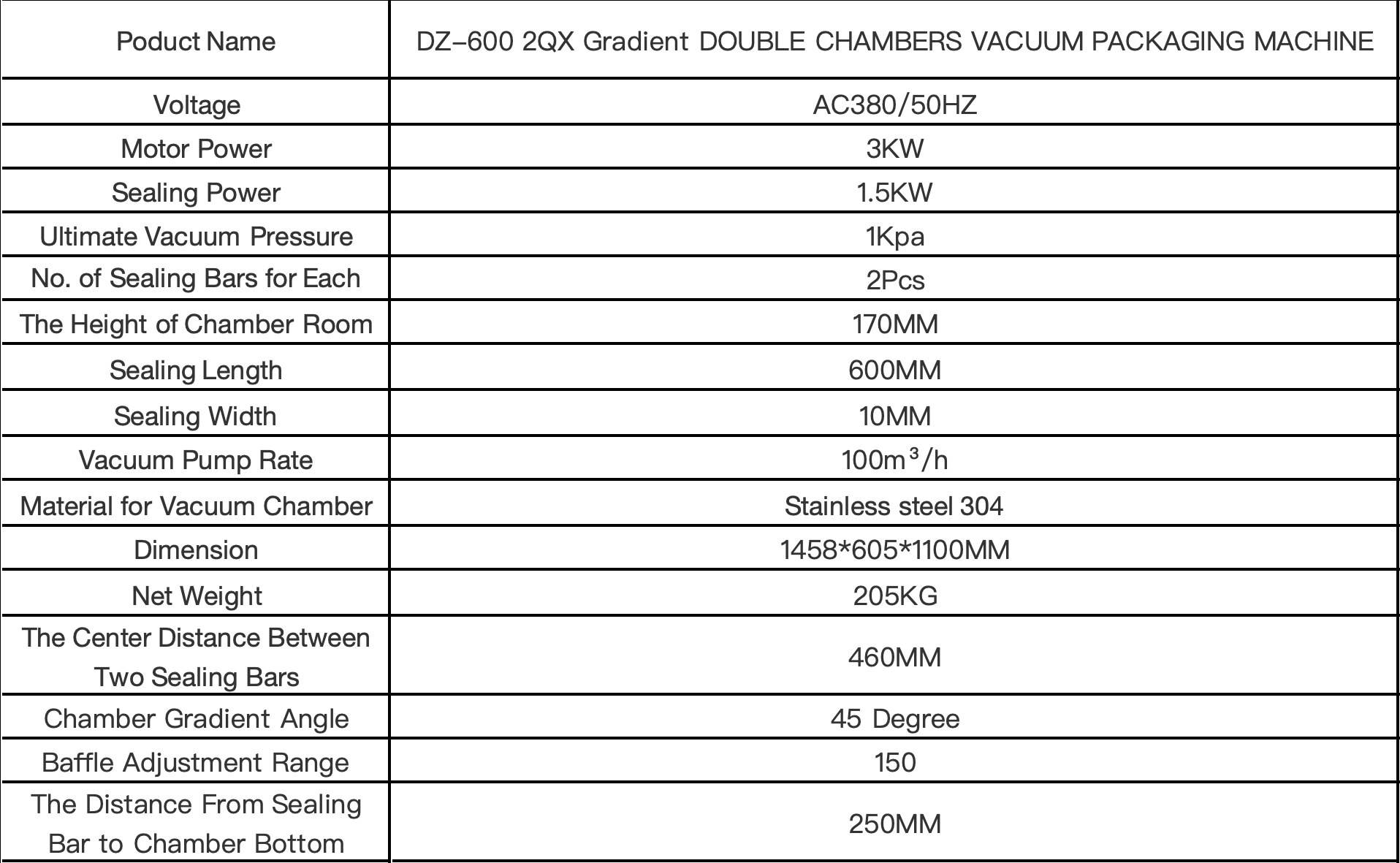

| Poduct Name | DZ-600 2QX Gradient DOUBLE CHAMBERS VACUUM PACKAGING MACHINE |

| Voltage | AC380/50HZ |

| Motor Power | 3KW |

| Sealing Power | 1.5KW |

| Ultimate Vacuum Pressure | 1Kpa |

| No. of Sealing Bars for Each Chamber | 2Pcs |

| The Height of Chamber Room | 170MM |

| Sealing Length | 600MM |

| Sealing Width | 10MM |

| Vacuum Pump Rate | 100m³/h |

| Material for Vacuum Chamber | Stainless steel 304 |

| Dimension | 1458*605*1100MM |

| Net Weight | 205KG |

| The Center Distance Between Two Sealing Bars | 460MM |

| Chamber Gradient Angle | 45 Degree |

| Baffle Adjustment Range | 150 |

| The Distance From Sealing Bar to Chamber Bottom | 250MM |

1.Anti corrosion of substances such as oil and salt, easy to clean

Food packaging safety and hygiene

material thickness 3mm

Vacuum chamber material SUS304

Fuselage fillet process R7 °

2.Flexible adjustment of vacuum chamber depth

Adapt to multi size bags that tilt without spillage

Vacuum chamber depth 17cm, 9-layer adjustable gear

3.Intelligent operation panel is easy to get started with

Anti electromagnetic, dust, stable and durable shaking

Intelligent industrial grade operation panel with high stability

- hot seal strip can be embedded into the metal particle bag, it can be printed with clear and beautiful date handwriting

6.product size