BF550+BSN5030 Automatic L Sealer and Shrink Tunnel L Bar Heat Shrink Tunnel Packaging Machine

• Teflon coated, thermostable and anti-sticky aluminum alloy cutter ensures good sealing without cracking, coking and smoke pollution.

• Horizontal and vertical photo-eyes detect products, ensure the machine wrap the products in suitable-size bags according to their dimensions.

• Easy to Change-over packed products, the package size can be adjusted without tooling, and adjust wasted film winding speed automatically.

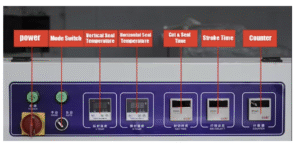

• The digital temperature controller with PID ensures the sealing temperature is sensitive and accurate. The temperature is adjustable according to film thickness and material.

• The blade self-protects from accidental cutting, and avoid to damage the product.

• The safety guard on the sealing unit ensures the safe of operator.

• Wrap multi-piece products in one package for promotion.

• Connect with production line easily, “no product, no package”.

The machine consists of an automatic L bar sealing machine and a heat shrinking tunnel, to wrap products into packages, and shrink packages automatically with high efficiency, the max. speed is 30 packages per minute.

| Model | BF-550 | Model | BSN5030 |

| Voltage | 220V 50/60HZ | Voltage | 220-380V 50-60HZ 3 phase |

| Power | 1.26KW | Power | 11KW |

| Packing speed | 15-30 pcs/min | Max loading | 20kg |

| Max packing size (W+H) | H≤250mm | Tunnel size | 1200*500*300mm |

| Max sealing size | (W+H)≤420mm | Conveyor speed | 0-15m/min |

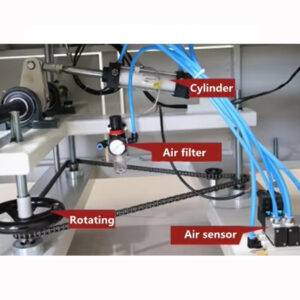

| Air pressure | 6-8kgf/c㎡ | Dimension | 1600*760*760mm |

| Dimensions (L*W*H) | 1900*1075*1540mm | Weight | 90kg |

| Weight | 350kg | Volume after machine packaging | 1650*710*820 =0.95m³ |

| Max loading | 40kg | Applicable shrink film | POF、PVC |