Description of plastic film wrapping machine:

It adopts jet structure, and suitable for batch shrink production of software, biscuit, printing and floor, chinaware, beverage, beer etc. Intlligence temperature control and strong turbing motor. Conveyor is alternative with Aluminum Roller or Teflon Mesh Overlay. It’s suitable for PVC, POF, PP, PE shrink film.

Future of plastic film wrapping machine:

1.Electronic continuously variable transmission, stable and reliable , long life, low noise.

2.Far infrared quartz heating tube , working continuously generated when infrared radiation , with a strong wind cycle , the temperature of the heating chamber becomes more uniform , while saving energy .

3.Conveying part adopts high-power DC motor , can be variable speed, while carrying a higher rate .

4.Can work long hours , but also stable and reliable operation .

5.Using a special mechanical structure design , more beautiful , luxurious , leaving the maintenance becomes easy and convenient.

|

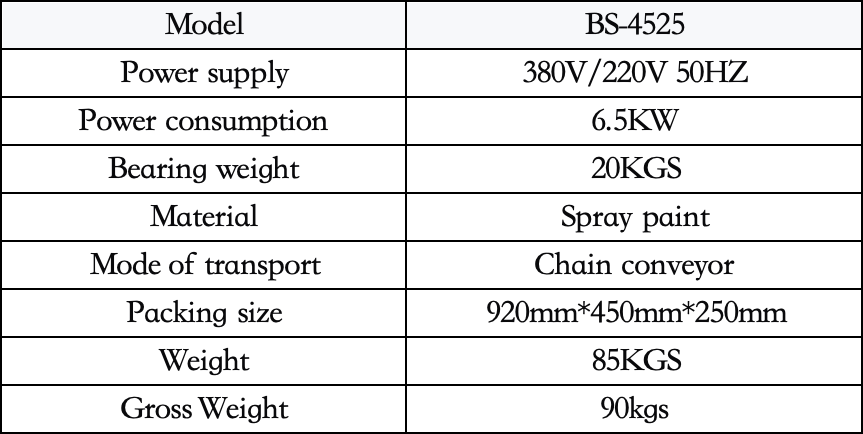

Model

|

BS-4525

|

|

Power supply

|

380V/220V 50HZ

|

|

Power consumption

|

6.5KW

|

|

Bearing weight

|

20KGS

|

|

Material

|

Spray paint

|

|

Mode of transport

|

Chain conveyor

|

heat shrink tunnel size |

920mm*450mm*260mm

|

|

Weight

|

85KGS

|

|

Gross Weight

|

90kgs

|