Automatic Sealing and Cutting Shrink Wrapping Packaging Machine

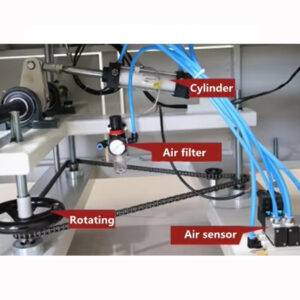

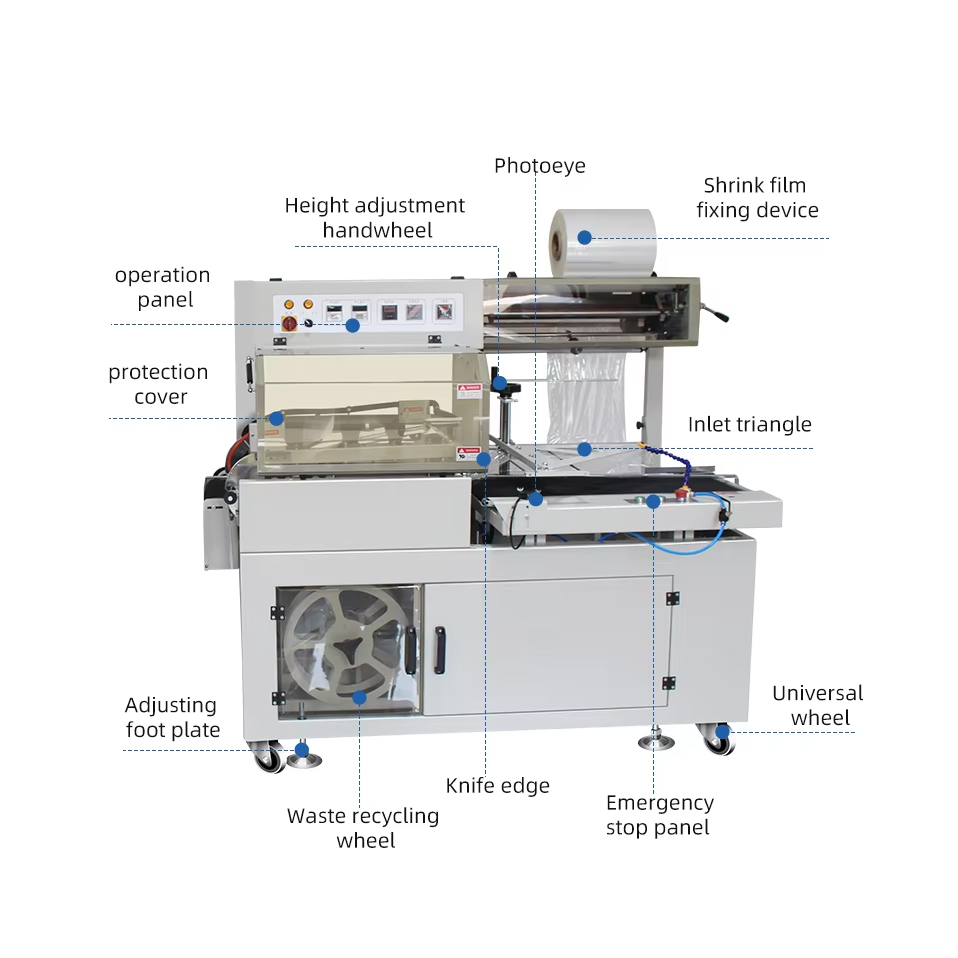

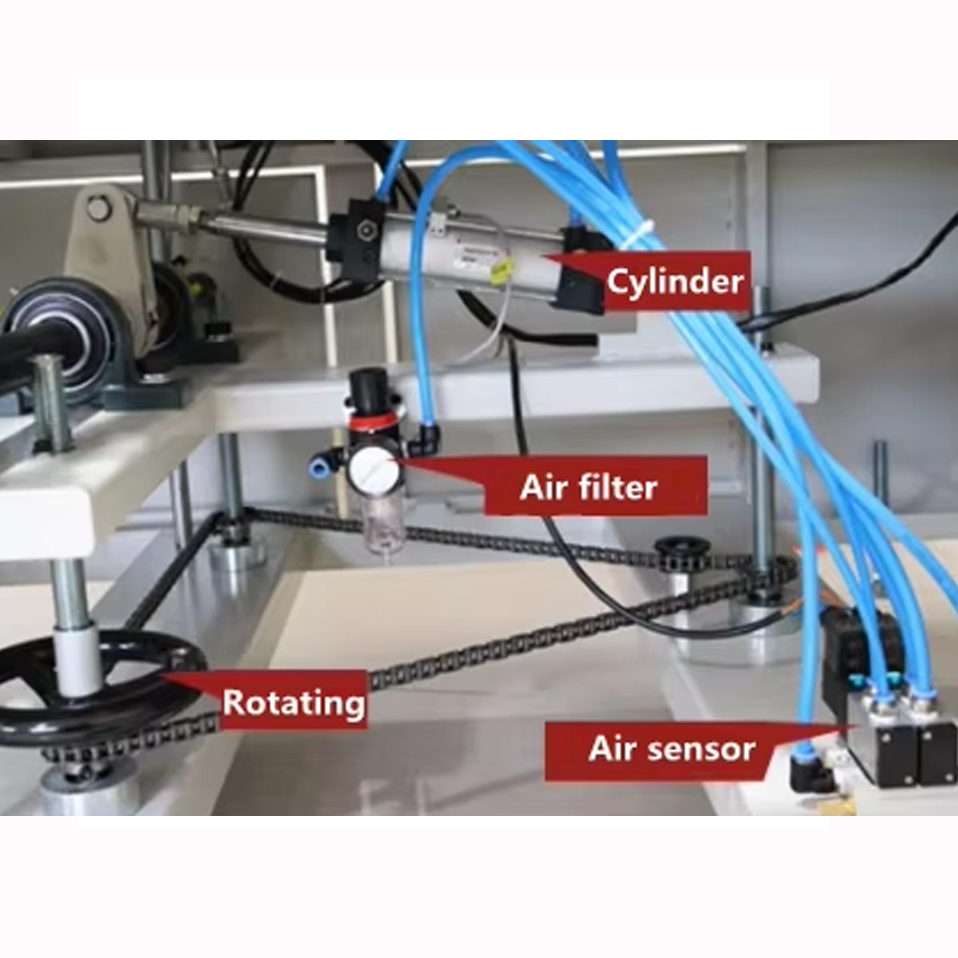

The L type automatic sealing machine can be used for automatic online shrink packaging of products. It uses photoelectric to automatically detect the products.

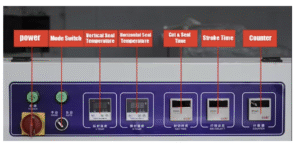

It can choose two modes of automatic feeding or manual feeding.

It adopts half-folding film and can seal the other three sides. The constant temperature heating sealing and cutting system can be used for sealing and cutting various industrial standard heat sealing films such as PE, PVC, POF, etc.

When the product size is changed, it only needs to be adjusted simply by the hand wheel, without replacing any parts, reducing the product replacement time and making it easier to operate.

The speed-adjustable front-end feeding system and the back-end storage work platform enable the whole machine to achieve high-speed and unmanned automatic operation.

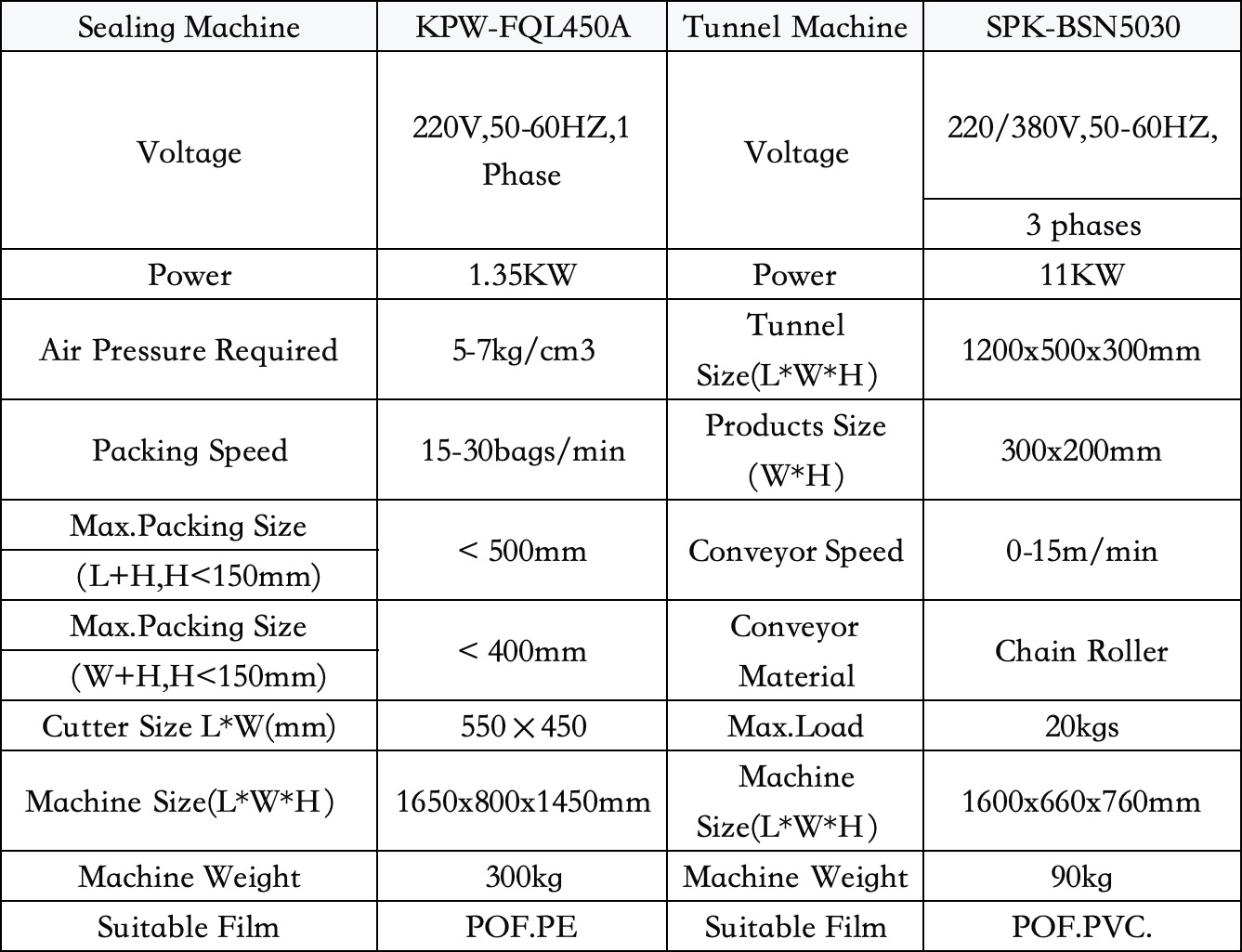

|

Sealing Machine |

KPW-FQL450A |

Tunnel Machine |

KPW-BSN5030 |

|

Voltage |

220V,50-60HZ,1 Phase |

Voltage |

220/380V,50-60HZ, 3 phases |

|

Power |

1.35KW |

Power |

11KW |

|

Air Pressure Required |

5-7kg/cm3 |

Tunnel Size(L*W*H) |

1200x500x300mm |

|

Packing Speed |

15-30bags/min |

Products Size(W*H) |

300x200mm |

| Max.Packing Size

(L+H,H<150mm) |

< 500mm |

Conveyor Speed |

0-15m/min |

| Max.Packing Size

(W+H,H<150mm) |

< 400mm |

Conveyor Material |

Chain Roller |

|

Cutter Size L*W(mm) |

550×450 |

Max.Load |

20kgs |

| Machine Size(L*W*H) | 1650x800x1450mm | Machine Size(L*W*H) | 1600x660x760mm |

| Machine Weight | 300kg | Machine Weight | 90kg |

| Suitable Film | POF.PE | Suitable Film | POF.PVC. |